|

|

Real-Time Operations Tracking & Management Software |

|

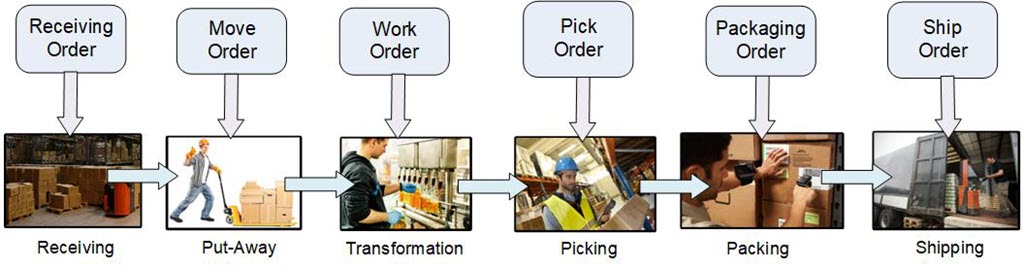

WIPtracker™ enables operations managers and their staff to efficiently manage operations in a single manufacturing plant or industrial distribution warehouse or, with SmartOps247, a widely separated network of such sites.

WIPtracker is also ideal for those organizations that need to comply with FDA and DOD regulations for materials tracking and traceability. It is essential for any organization that needs to track individually dimensioned rolls of material.

As well as tracking the flow of jobs and materials through manufacturing plants WIPtracker is ideal for those distribution warehouses that need to track secondary operations such as assembly, relabeling and kitting and for construction organizations that need to perform operations on materials before shipment to site.

At a practical level, WIPtracker is an affordable, integrated work-in-process tracking, warehouse management, and manufacturing execution system. WIPtracker also performs job and materials and tracking, and traceability data collection and can automatically exchange data with a wide-variety of ERP and accounting systems.

Most important WIPtracker is affordable and rapidly pays for itself by eliminating the need for intelligent grunt work, such as filling out paper forms or Excel spreadsheets or manually keying data into multiple different computer systems.

Please click here to learn more about the Capabilities of WIPtracker.

| Availability | Technology |

|

Data Sheets | Return on Investment |

| History | Multi-Site Operation | Videos | Capabilities |

| Technology |

|

Data Sheets |

| Availability | History | Return on Investment |

| Videos | Multi-Site Operation | Capabilities |

Copyright © Smart Operations Management LLC 2025